Don't worry, contact Our boss immediately

Don't rush to close it, now, please talk to our boss directly. Usually reply within 1 hour.

China's leading manufacturer of PCB Laser Dapaneling Machine

One-Stop PCB Depaneling Solutions

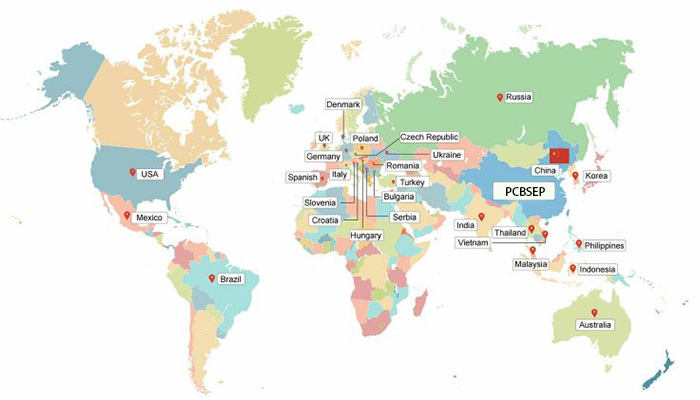

PCBSEP builds high-precision PCB Laser Depaneling Machines for high-volume OEMs. Eliminate mechanical stress, reduce scrap rates, and automate your SMT line with our Inline & Offline Singulation systems. Get a quote today.

Find the best PCB laser cutting machine supplier for your production. Learn how PCBSEP delivers precise, stress-free laser depaneling with global support.

1) Materials at a Glance Ceramics (Al₂O₃/AlN, HTCC/LTCC): Extremely hard, brittle, thermally conductive, low CTE. Mechanical tools induce cracks and…

UV laser depaneling delivers narrow kerf (≈20–50 µm), clean edges, and stress-free separation—raising panel yield and cutting rework versus routing,…

Explore our systems and pick the best fit for your line.