- Ceramics (Al₂O₃/AlN, HTCC/LTCC): Use UV (355 nm) with multi-pass, low fluence; picosecond beats nanosecond for the cleanest edges. Expect ±20–25 µm cut accuracy with minimal chipping when fixturing and extraction are dialed in.

- IMS (metal-core: Al/Cu): Non-contact laser depaneling avoids conductive swarf and stress. UV handles dielectrics; Green (532 nm) improves coupling to copper. Plan for narrow kerf and recipe-driven passes; consider DFM to minimize full-thickness metal removal when possible.

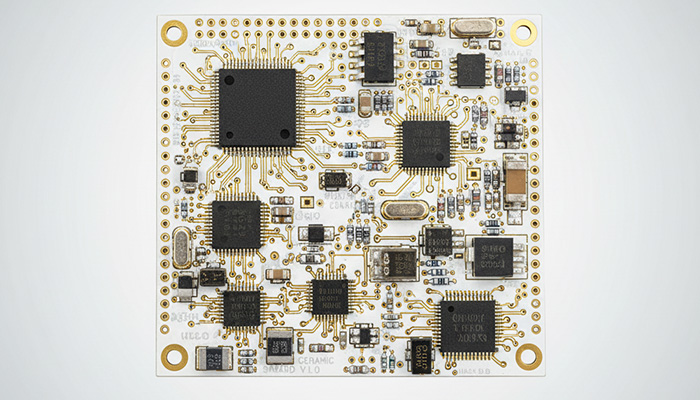

1) Materials at a Glance

Ceramics (Al₂O₃/AlN, HTCC/LTCC): Extremely hard, brittle, thermally conductive, low CTE. Mechanical tools induce cracks and particles; laser ablation is wear-free.

IMS (Insulated Metal Substrates): Copper circuit + dielectric + Al/Cu (sometimes stainless) core. Great for thermal spreading but reflective/heat-sinking—needs tuned laser strategy.

2) Wavelength & Pulse Regime (What Works Best)

Ceramics

- UV 355 nm is the default; ps-UV gives the smallest HAZ and least micro-cracking.

- Use multi-pass cutting with low fluence and higher rep rates; keep velocity constant.

IMS

- Dielectric & soldermask: UV ablates cleanly.

- Copper: 532 nm couples better than IR; UV also works with tuned fluence.

- Metal core: full-depth laser removal is possible but DFM (e.g., local recess, thinner core, partial score) often yields higher takt and less heat load.

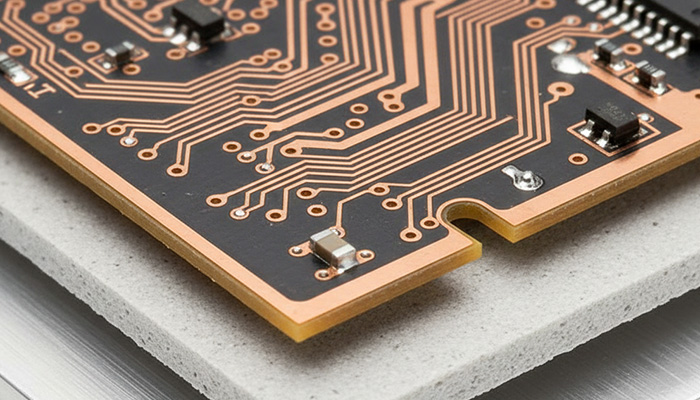

3) Edge Quality Playbook (Ceramic & IMS)

- Pass strategy: Many shallow passes > fewer deep passes (reduces chipping/HAZ).

- Optics: Telecentric lens + well-calibrated galvo; verify spot size at focus.

- Extraction: High-efficiency fume/debris removal; lens protection shields.

- Cooling cadence: For thick or high-k stacks, interleave passes or scan segments to limit local heat.

- Verification: Inspect with micrographs; track HAZ width, edge roughness, and any micro-cracks.

4) Fixturing & Vision

- Vacuum hold-down on granite/bridge platforms; add carriers for thin LTCC/HTCC or small IMS coupons.

- Flatness control: Height sensing if the stack warps under heat load.

- Registration: CCD fiducials or pattern matching; if no targets, use DIL modules.

- Bad-board handling: Mark and skip defective circuits to protect yield.

5) Design-for-Laser (DFL) Rules of Thumb

- Minimum radius: ≤ 0.1–0.2 mm is routine with UV (recipe/model dependent).

- Slot/window width: As low as ~0.2–0.3 mm with tuned passes.

- Keep-out: State your copper/component keep-out; UV enables very tight distances.

- IMS tip: Where possible, avoid long full-thickness core cuts—use notches, thinner cores, or local reliefs to shorten metal path length.

6) Throughput Math (Simple Estimator)

Panel time (rough):

Tpanel ≈ (Total cut length / vector speed)

+ (N_fid × align_time)

+ load/unload + overhead

Laser often wins OEE by eliminating bit changes, tool wear drift, and swarf clean-ups, especially on complex contours.

7) IMS-Specific Pitfalls & Fixes

- Reflectivity & heat sink effect: Use Green/UV, more passes, and steady scan speeds; pre-heat is usually unnecessary if pass strategy is right.

- Conductive debris risk (mechanical): Laser produces no metallic swarf; pair with good extraction to keep edges clean.

- Burr at copper edges: Slight defocus on finishing pass + proper fluence smooths the lip.

8) What “Good” Looks Like (Targets)

- Cut accuracy: ~±20–25 µm

- Repeatability: ~±2–3 µm

- Kerf: ~20–60 µm (material/recipe dependent)

- Ceramic chipping: None visible at low magnification; micro-chipping minimized in micrographs

- IMS edges: Swarf-free, minimal discoloration, no delamination of dielectric

9) Model Picks (by Job Type)

- Small/medium ceramic or IMS coupons: DirectLaser H1 (300×350 mm)

- Offline daily ceramic/IMS panels: DirectLaser S2 (350×350 mm, granite)

- Inline PCBA depaneling: DirectLaser S4 (track-inline, 350×350 mm)

- Inline higher UPH: DirectLaser H3 (dual-platform, 300×300 mm)

- Large/multi-up arrays: DirectLaser H3 330D (350×520 mm)

- Big or complex boards / thick stacks: DirectLaser H5 (520×520 mm; up to 580×580)

10) Sample-Cut Checklist (Send This for Fast Results)

Material + thickness (Al₂O₃/AlN/LTCC/HTCC or IMS core) · Copper stack-up · Dielectric type/thickness · Target kerf/edge limits · Keep-out to copper/components · Panel/board size & array · Takt/UPH · Inline/Offline + MES · CAD (Gerber/ODB++/DXF/Excellon) · Reference photo.

FAQ (Short)

- Will UV/Green damage nearby parts? Proper multi-pass recipes keep HAZ low; it’s non-contact (no mechanical stress).

- Can we cut fully through an aluminum core? Yes, but takt may drop—consider DFL to reduce metal path length or use a hybrid approach (partial relief + finish cut).

- How do we prove quality? Provide micrographs, edge-roughness and HAZ measurements, and—on IMS—resistance/insulation checks across the cut.