| Item | ZAM310H |

| Platform Type | Single Platform |

| Processing Area | 350 × 350 mm |

| Repeatability | ±2 μm |

| Overall Precision | ±25 μm |

| X/Y Resolution | 1 μm |

| Material Thickness | ≤ 2.0 mm |

| Platform Structure | Steel Structure |

| Motor Type | Servo Motor |

| Laser Type | Nanosecond |

| Laser Power | 15 W |

| Telecentric Lens Range | 50 × 50 mm, f = 100 mm;Domestic Galvanometer |

| CCD System | Axial-parallel |

| Positioning Accuracy | 0.01 mm |

| Camera Resolution | 130 MP |

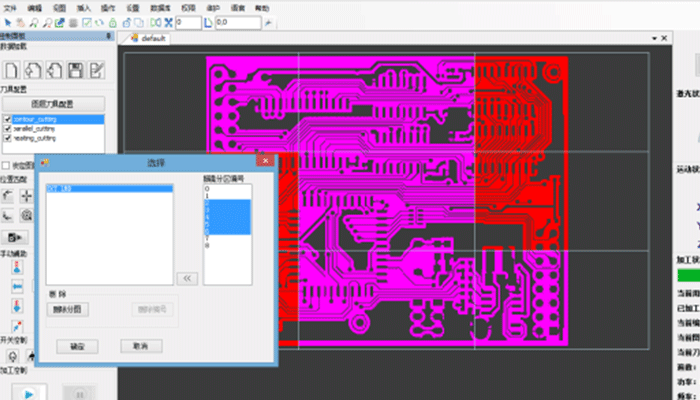

| Control Software | DreamCreaTor 3 |

| Data Processing Software | Circuit CAM 7.5 Standard |

| File Formats | LMD, Standard Gerber (RS-274-D), Extended Gerber (RS-274-X), DXF, Excellon, Sieb & Meier, HP-GL, Barco DPF, ODB++ |

| Operating Environment | 22 °C ±2 °C |

| Power Supply | 380 VAC / 50 Hz / 2 kW |

| Weight | Approx. 580 kg |

| Dimensions (L×W×H) | 930 × 1270 × 1600 mm |

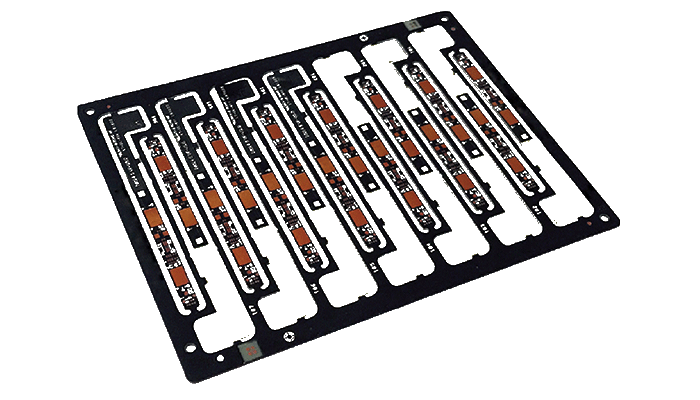

Stress-free separation of assembled boards with dust-free edges. Cuts close to components and copper without mechanical load, improving yield. (Laser depaneling PCB / laser cut PCB board)

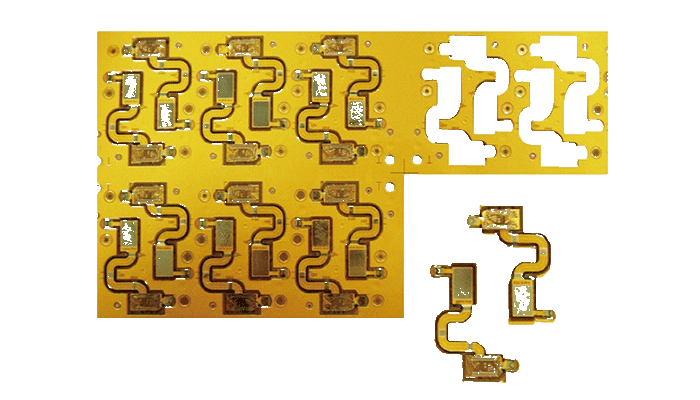

Fine trimming and singulation around connector “gold-finger” areas on FPC/PCB. Protects plating quality with tight tolerances and low heat input. (Gold-finger laser cutting)

Clean, burr-free outlines on flexible circuits. Narrow kerf and minimal HAZ for tight radii and complex shapes—ideal for rigid-flex tails. (FPC laser cutting / PCB laser cutting)

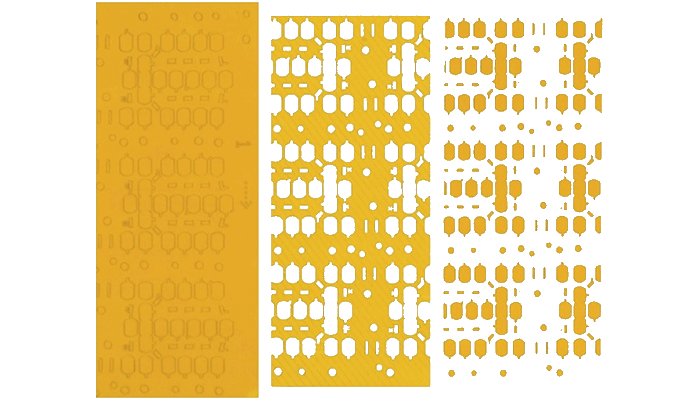

Precise window openings and perimeter trimming on FPC coverlay. Consistent edges with no delamination, supporting PI/LCP stacks. (Coverlay laser cutting for rigid-flex/FPC)

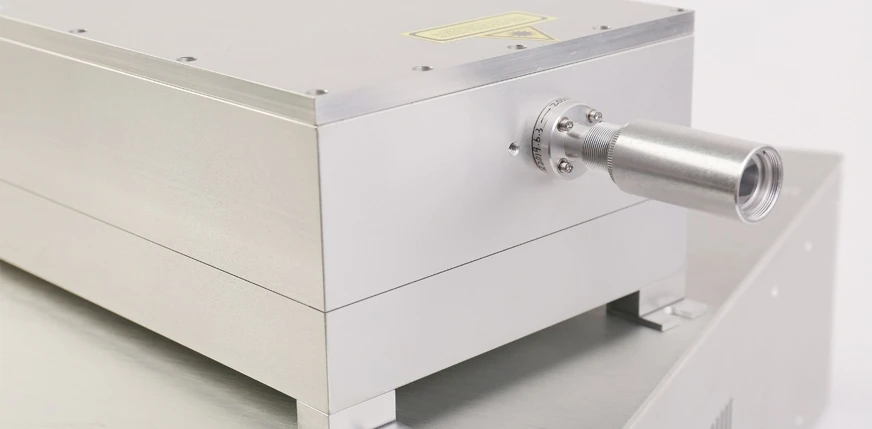

| Specification | 15 W UV Laser |

| Wavelength | 355nm |

| Max. Average Power | >15W@50KHz |

| Max.Pulse Energy | >300μJ |

| Repetition Rate | 40~300KHz |

| Pulse Width | <15ns |

| Beam Circularity | >90% |

| Diameter at window | ≈0.55mm |

| Beam Quality (M²) | <1.2 |

| Beam Divergence | <2mrad |

| Energy Stability | <3% RMS |

| Point Stability | <20μrad / ºC |

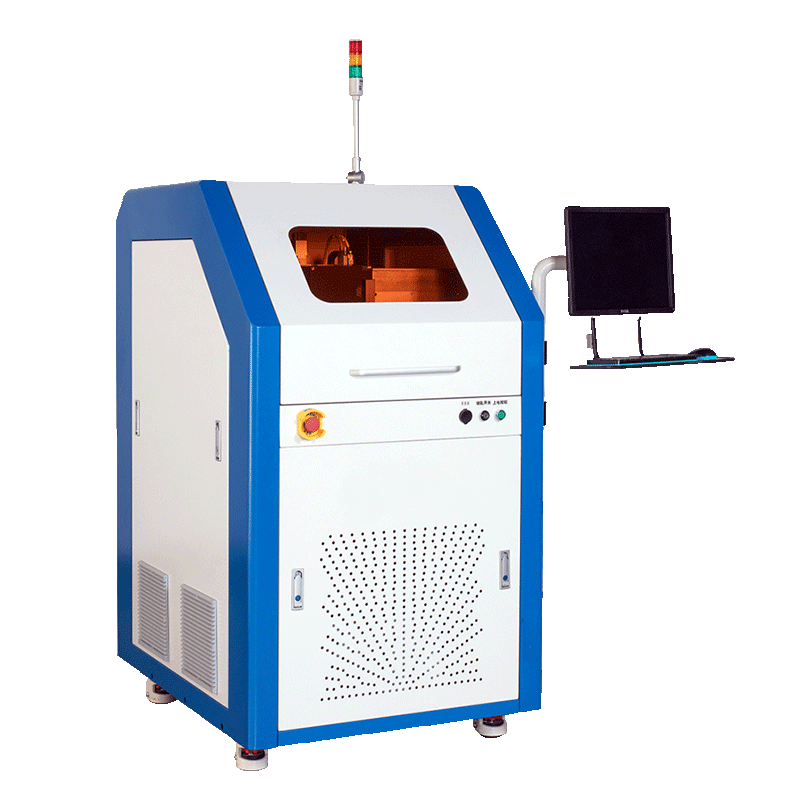

Entry-level UV depaneler for low/medium takt SMT. Compact footprint, stable steel frame, cost-effective for standard FR-4/FPC jobs.

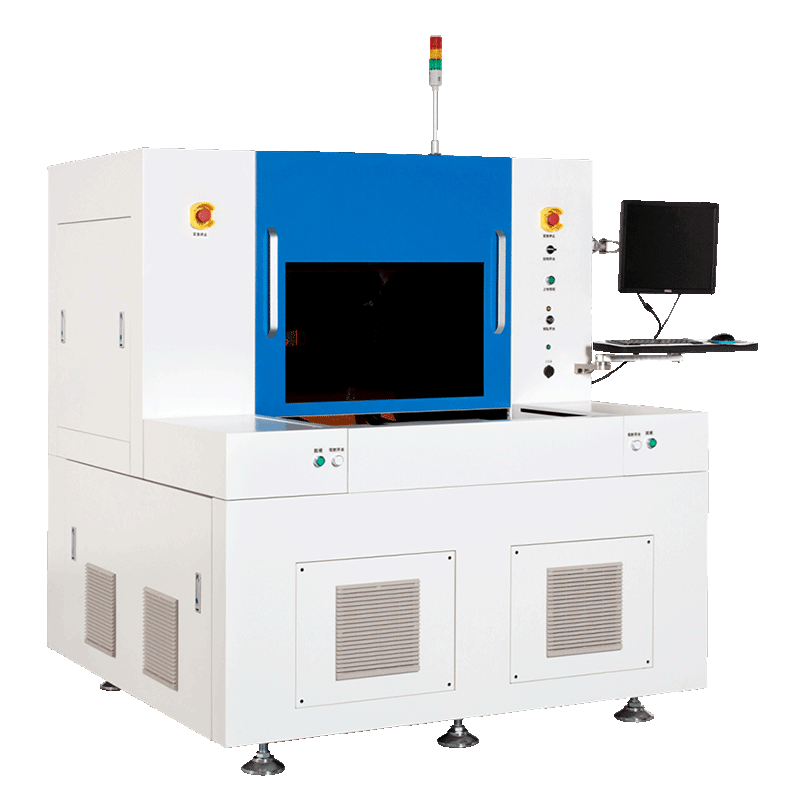

Two shuttle tables cut while you load the next panel—significant throughput gain vs. single-platform. Suited to standard SMT depaneling.

High-volume depaneling for large or multi-up panels. Faster cycle time from overlapping load/unload; optional inline upgrade pathway.

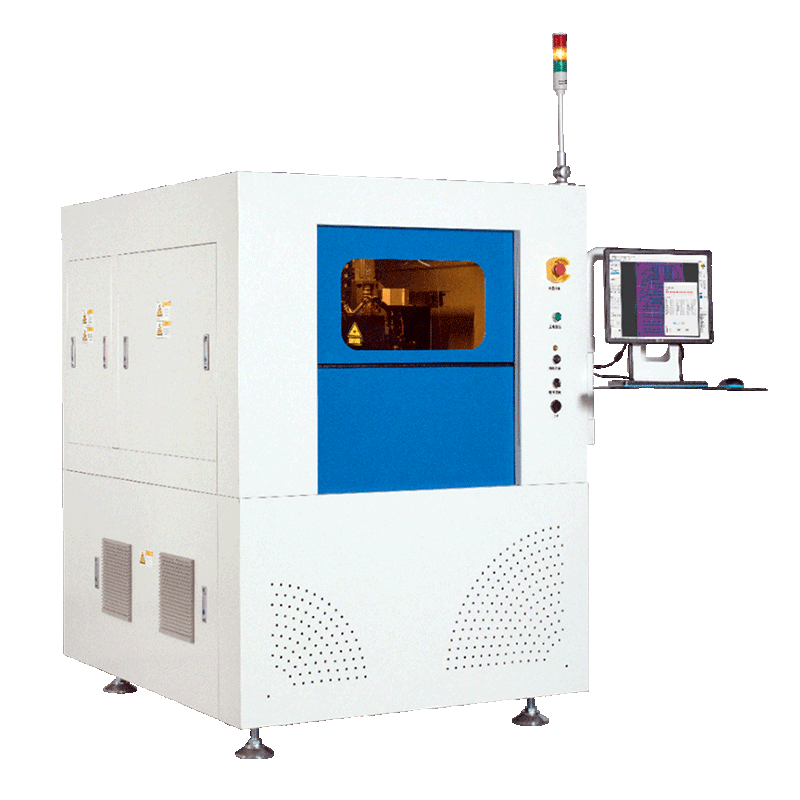

Drops straight into SMT lines; supports barcode/traceability and MES. Fits any PCBA outline; ideal when you want no manual load/unload.

High-stability X/Y split-axis for thick copper, rigid-flex, and complex outlines. Ships offline; can be upgraded to inline (three-section conveyor).