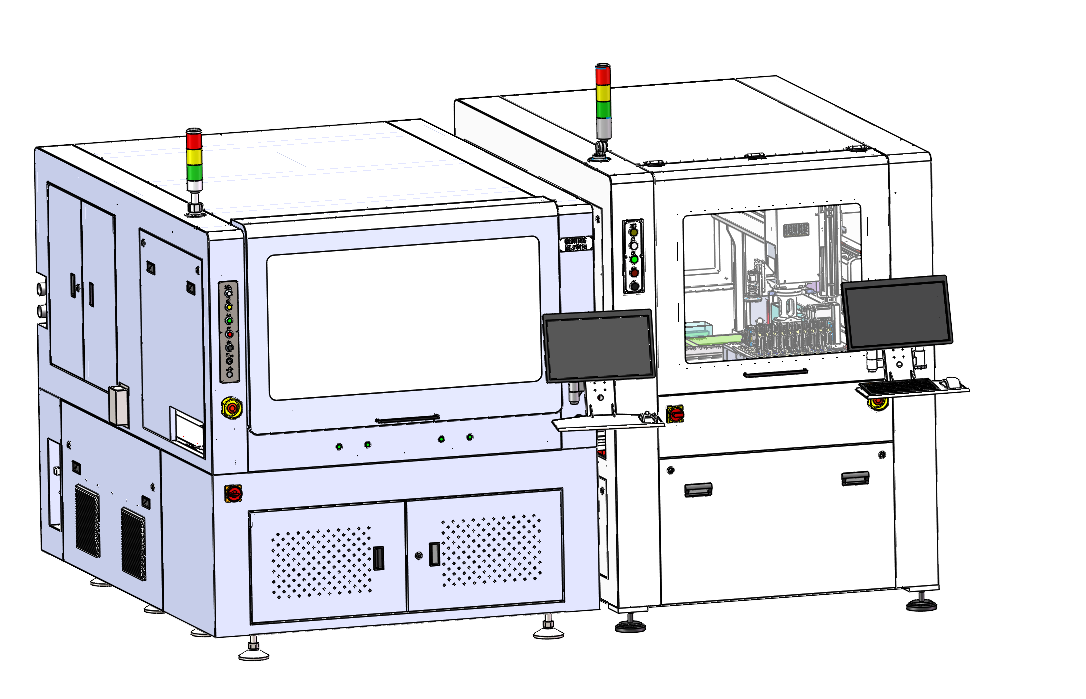

| Item | ZAM330 |

| Item | ZAM330 |

| Data processing SW | CircuitCAM 7 |

| Operation software | DreamCeaTor 3 |

| Laser | UV / Green / IR; Picosecond or Nanosecond |

| Max processing area | 300 mm x 300 mm (dual worktables) |

| Scan head | intelliSCAN + RTC5 |

| Telecentric lens | Wavelength-related |

| Mirrors | Wavelength / power-related |

| Motors | Servo motors |

| Motion control card | GTS-400 |

| CCD light source | Ring light |

| Industrial PC | CPU: i5; RAM: 4 GB DDR3; HDD: 1 TB |

| Display | 17" LCD |

| Platform structure | Marble/granite |

| Dimensions (W x D x H) | 1620 mm x 1770 mm x 2250 mm |

| Item | ZAM330 |

| Item | ZAM330 |

| Data processing SW | CircuitCAM 7 |

| Operation software | DreamCeaTor 3 |

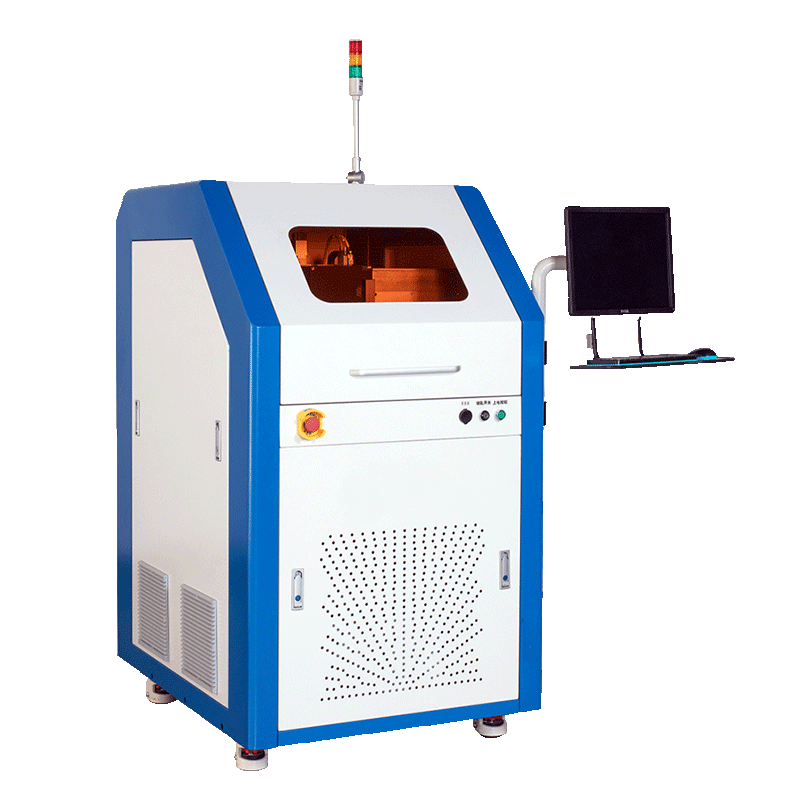

Micron-class repeatability for compact, high-accuracy work. Best when you need tight keep-outs and clean edges with minimal HAZ.

Entry-level UV depaneler for low/medium takt SMT. Compact footprint, stable steel frame, cost-effective for standard FR-4/FPC jobs.

High-volume depaneling for large or multi-up panels. Faster cycle time from overlapping load/unload; optional inline upgrade pathway.

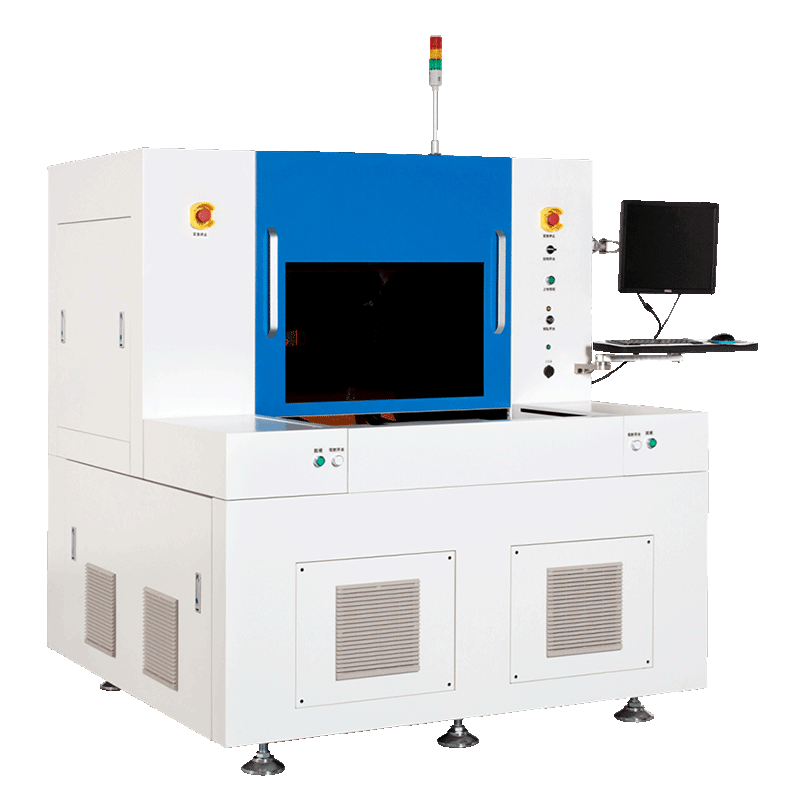

Drops straight into SMT lines; supports barcode/traceability and MES. Fits any PCBA outline; ideal when you want no manual load/unload.

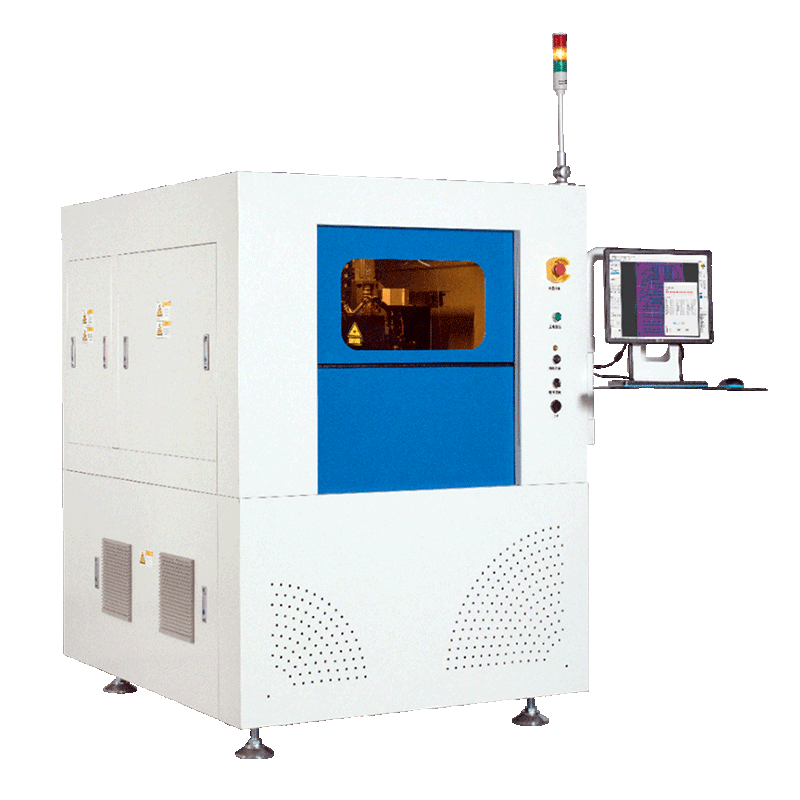

High-stability X/Y split-axis for thick copper, rigid-flex, and complex outlines. Ships offline; can be upgraded to inline (three-section conveyor).