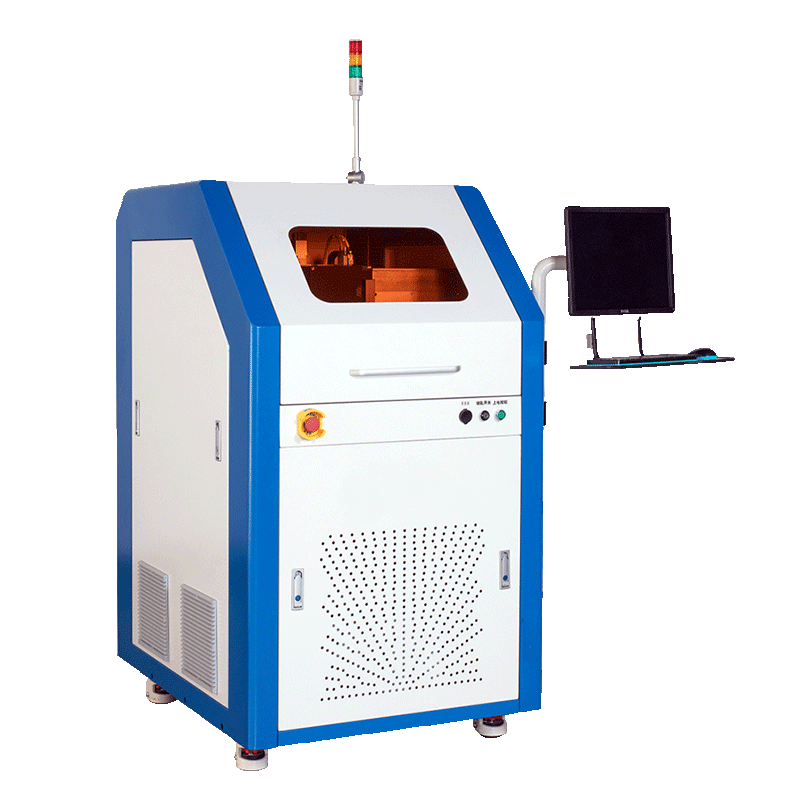

Micron-class repeatability for compact, high-accuracy work. Best when you need tight keep-outs and clean edges with minimal HAZ.

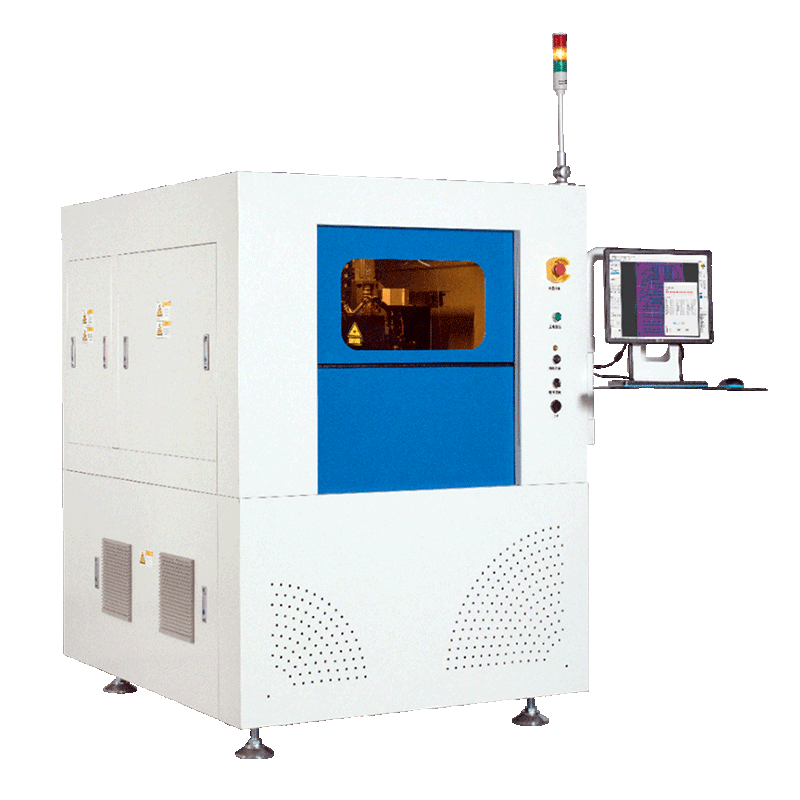

Entry-level UV depaneler for low/medium takt SMT. Compact footprint, stable steel frame, cost-effective for standard FR-4/FPC jobs.

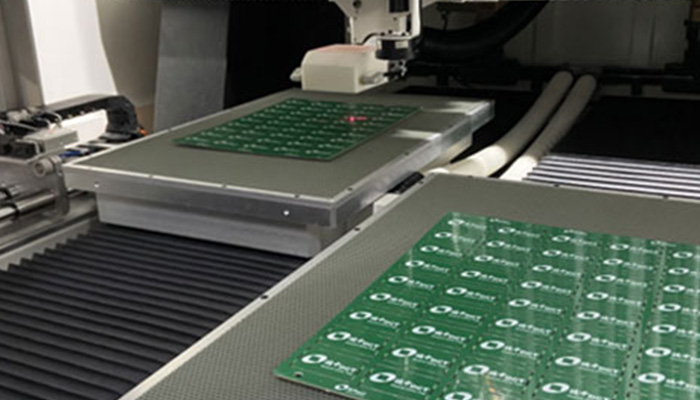

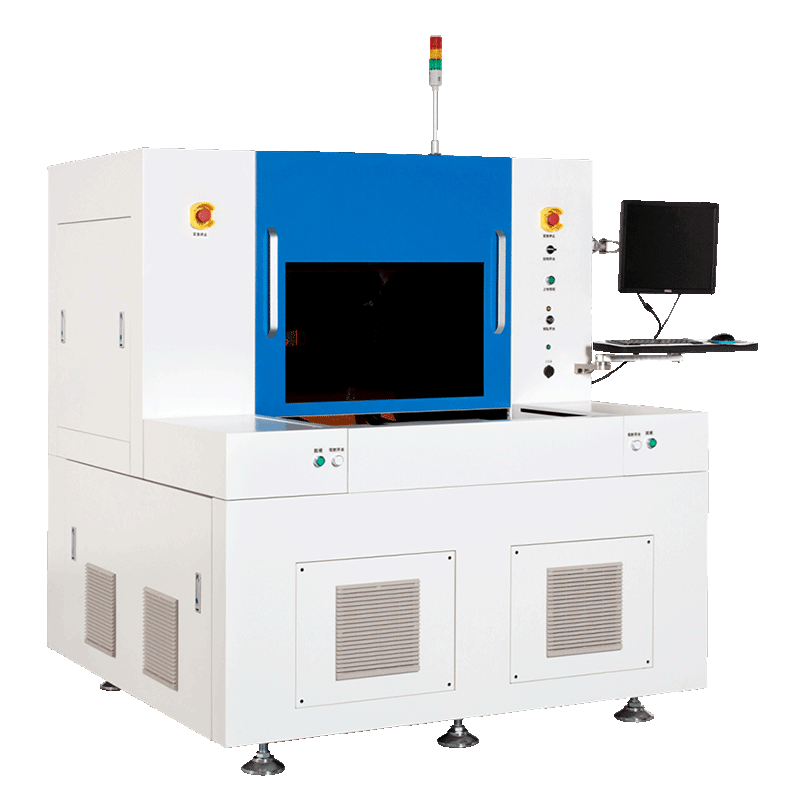

Two shuttle tables cut while you load the next panel—significant throughput gain vs. single-platform. Suited to standard SMT depaneling.

High-volume depaneling for large or multi-up panels. Faster cycle time from overlapping load/unload; optional inline upgrade pathway.

Drops straight into SMT lines; supports barcode/traceability and MES. Fits any PCBA outline; ideal when you want no manual load/unload.

High-stability X/Y split-axis for thick copper, rigid-flex, and complex outlines. Ships offline; can be upgraded to inline (three-section conveyor).