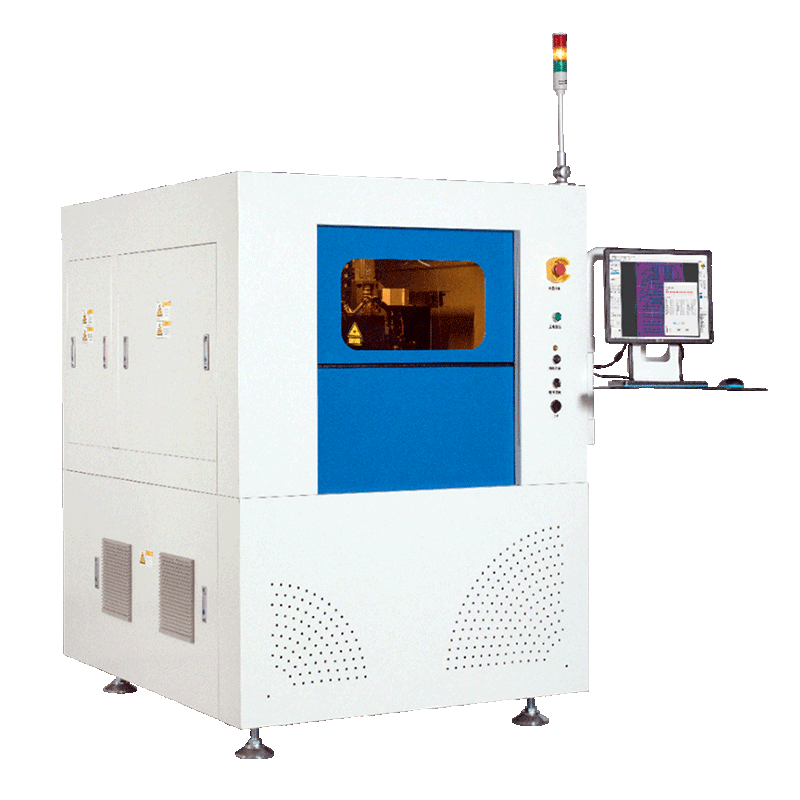

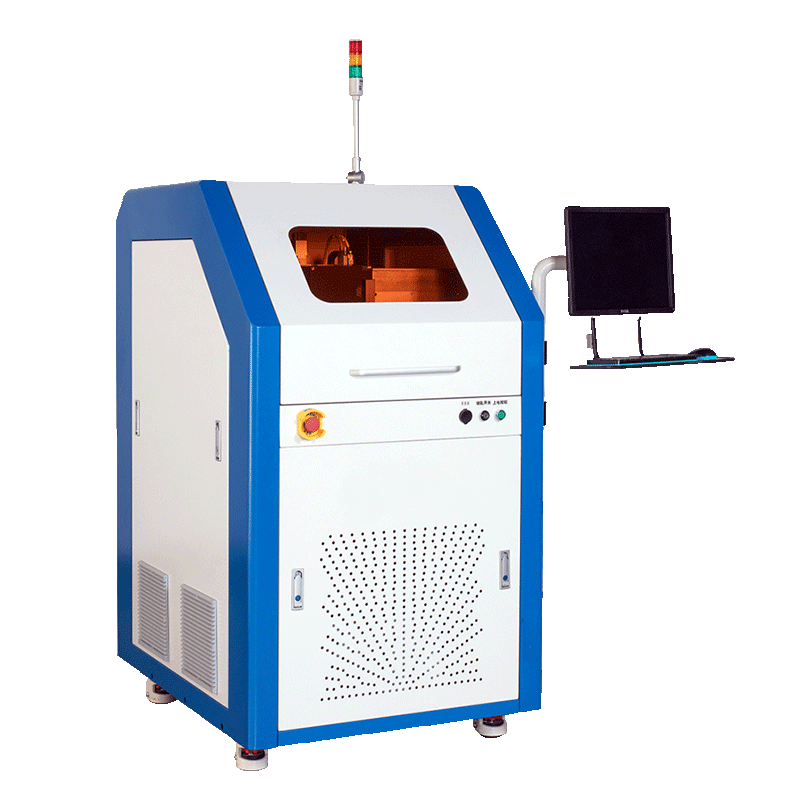

| Item | ZAM310L |

| Laser output power | 20 W (options: 15 W, 25 W, 35 W, 60 W) |

| Pulse type | Nanosecond / Picosecond (optional) |

| Laser wavelength | 355 nm / 532 nm |

| Max processing area | 520 mm × 520 mm (max supported 580 × 580 mm) |

| Platform | Granite table, linear motors |

| X/Y/Z resolution | 1 μm |

| Repeatability | ≤ ±2 μm |

| Data processing software | CircuitCAM 7.5 Standard |

| Control software | DreamCreaTor 3 |

| Camera target alignment | Optional |

| Industrial dust extraction | Optional |

| Dimensions (W × H × D) | 1,250 mm × 1,560 mm × 1,760 mm |

| Weight | 1,500 kg |

| Power | 380 VAC / 50 Hz, 3.5 kW |

| Ambient temperature | 22 °C ±2 °C |

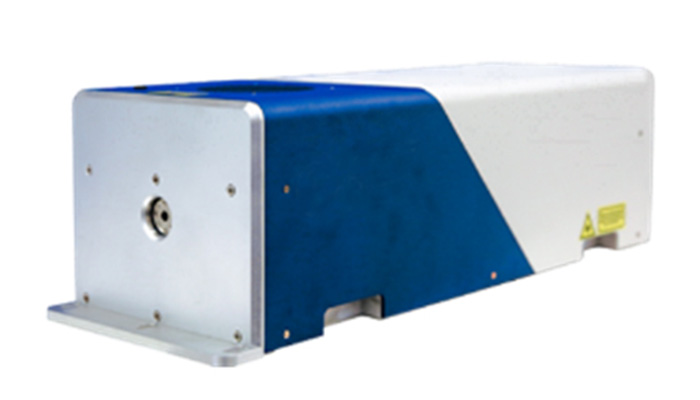

| Specification | 15–60 W Nanosecond UV Laser |

| Power options (UV) | ≥20 W model shown; 15/25/35/60 W available |

| Wavelength (nm) | 355 |

| Average power (W) | >20 @ 50 kHz |

| Pulse energy (µJ) | >300 |

| Repetition rate (kHz) | 40–300 |

| Pulse width (ns) | <15 |

| Beam circularity (%) | >90 |

| Beam diameter at window (mm) | ≈0.55 |

| Beam quality M² | <1.2 |

| Beam divergence (mrad) | <2 |

| Energy stability (% RMS) | <3 |

| Pointing stability (µrad/°C) | <20 |

| Polarization ratio | >100:1 |

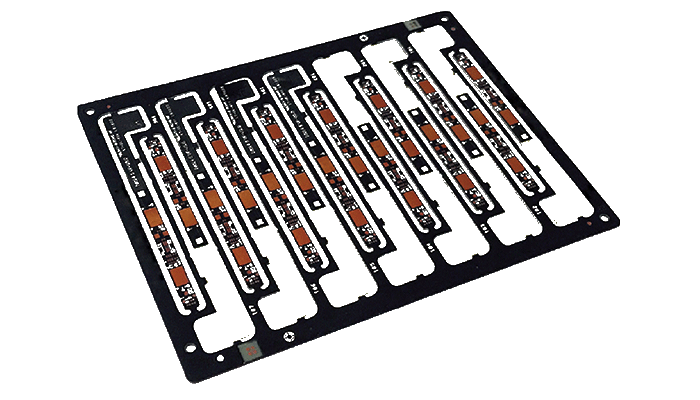

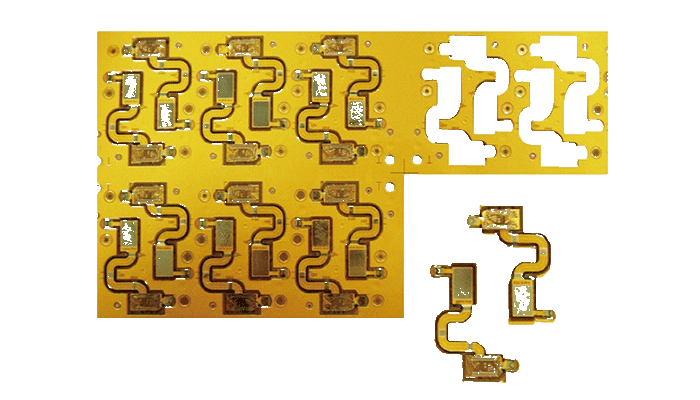

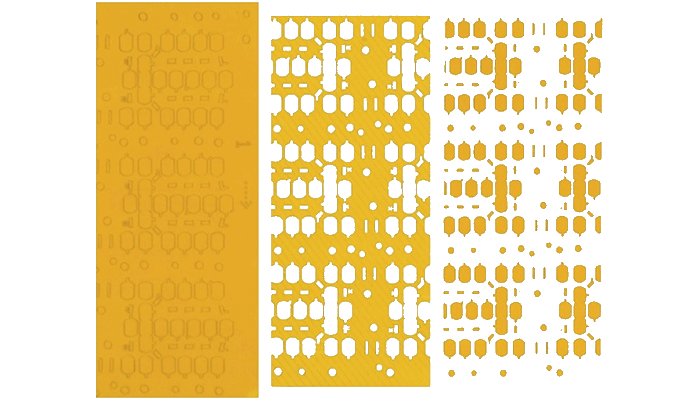

Micron-class repeatability for compact, high-accuracy work. Best when you need tight keep-outs and clean edges with minimal HAZ.

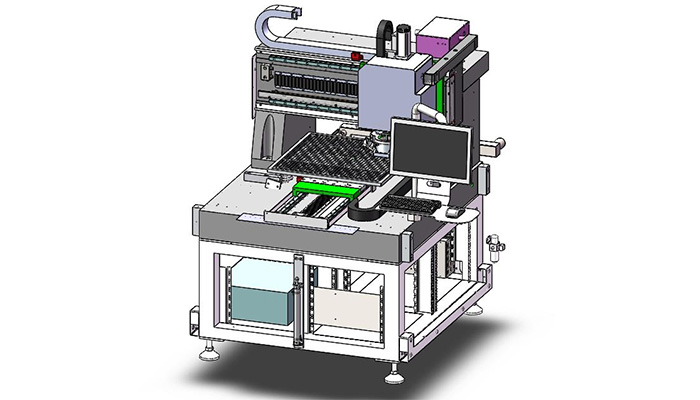

Entry-level UV depaneler for low/medium takt SMT. Compact footprint, stable steel frame, cost-effective for standard FR-4/FPC jobs.

Two shuttle tables cut while you load the next panel—significant throughput gain vs. single-platform. Suited to standard SMT depaneling.

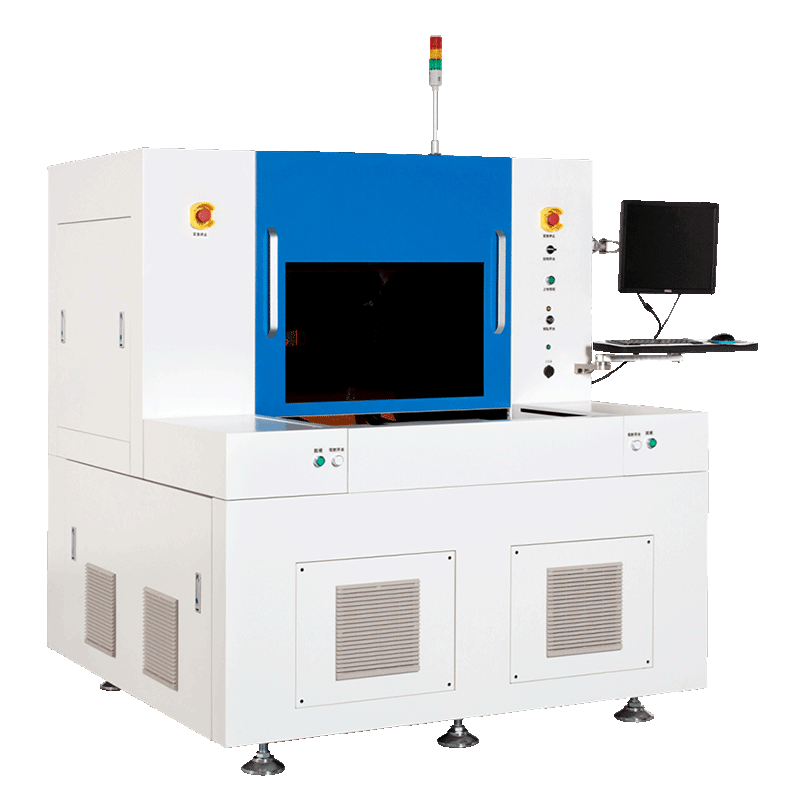

High-volume depaneling for large or multi-up panels. Faster cycle time from overlapping load/unload; optional inline upgrade pathway.

Drops straight into SMT lines; supports barcode/traceability and MES. Fits any PCBA outline; ideal when you want no manual load/unload.