Don't worry, contact Our boss immediately

Don't rush to close it, now, please talk to our boss directly. Usually reply within 1 hour.

China's leading manufacturer of PCB Laser Dapaneling Machine

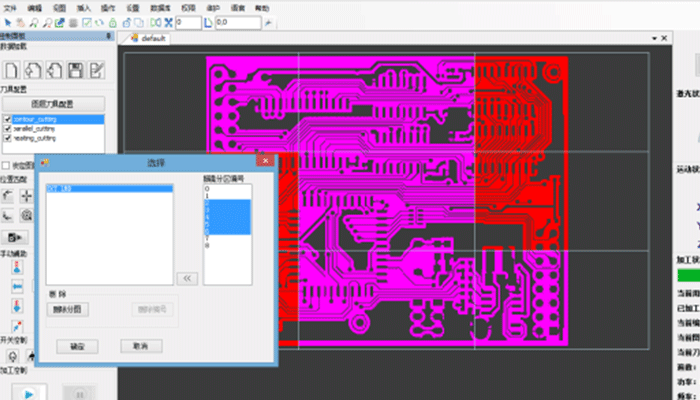

One-Stop PCB Depaneling Solutions

| Model | Working Area (X×Y) | Cutting Precision | Repeat Precision | Architecture / Mode | Typical Use | Materials |

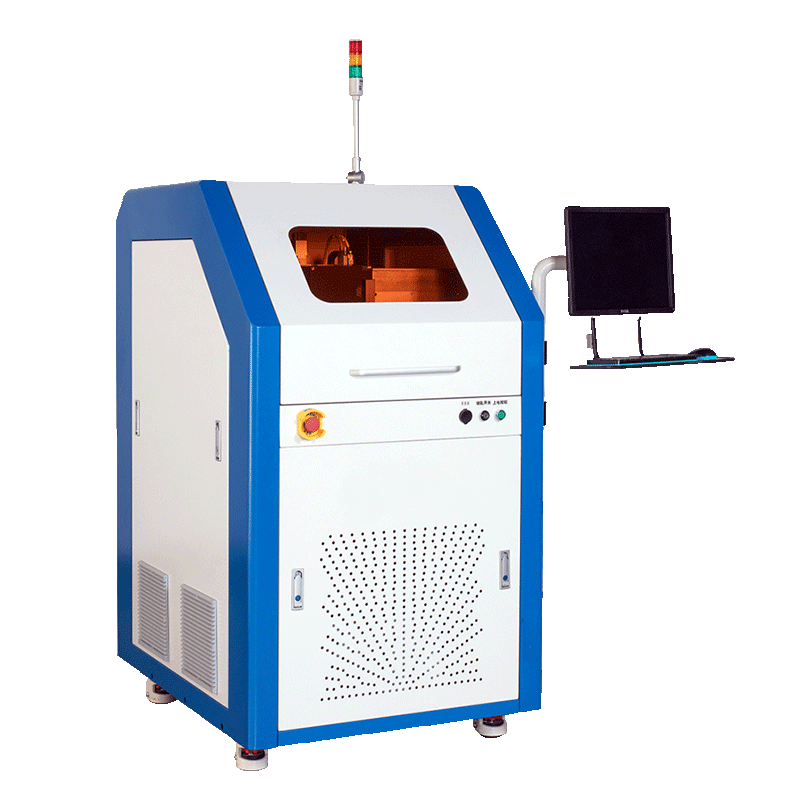

| DirectLaser H1 | 350×350 mm | ±25 µm | ±2 µm | Single-platform / Offline | Compact, tight keep-outs on FR-4 & FPC | FR-4, FPC/PI, Ceramics, IMS |

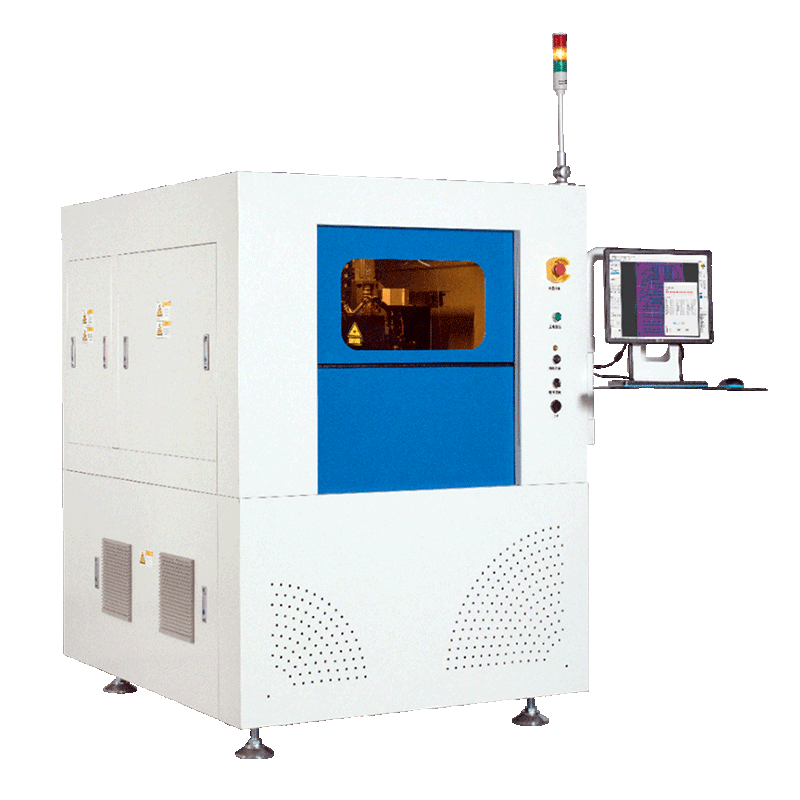

| DirectLaser S2 | 350×350 mm | ±20 µm | ±2 µm | Granite table / Offline | Daily SMT depaneling for FR-4/FPC | FR-4, FPC/PI, LCP |

| DirectLaser S4 | 350×350 mm | ±20 µm | ±3 µm | Track-inline (3-step) | Inline PCBA depaneling with full traceability | FR-4, FPC/PI, LCP |

| DirectLaser H3 | 300×300 mm | — | — | Dual-platform / Inline | Continuous cutting, high UPH inline | FR-4, FPC/PI, LCP |

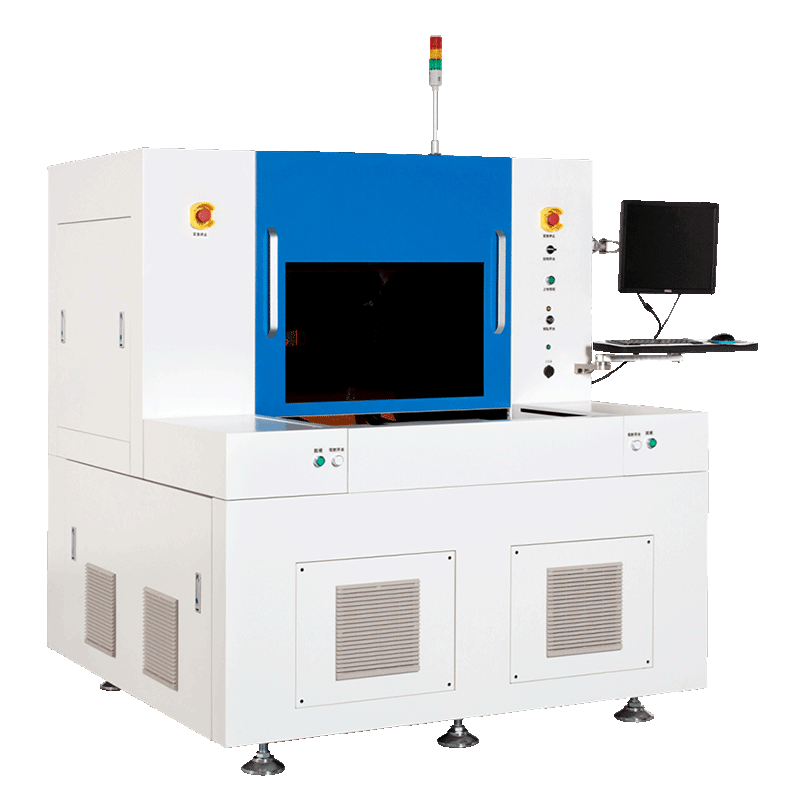

| DirectLaser H3 330D | 350×520 mm | ±20 µm | ±2 µm | Dual-platform / Offline (inline upgrade opt.) | Post-placement depaneling, coverlay windows, large/multi-up panels | FR-4, FPC/PI, LCP |

| DirectLaser H5 | 520×520 mm (max 580×580) | — | ≤±2 µm | Bridge-gantry, granite + linear motors (Offline) | Large/complex boards, rigid-flex, IMS | FR-4, FPC/PI, Ceramics, IMS |